Portable Industrial Videoscope Procurement Guide: Scientific Selection for Precision Industrial Inspection

Release time:2025-08-15 Click:677

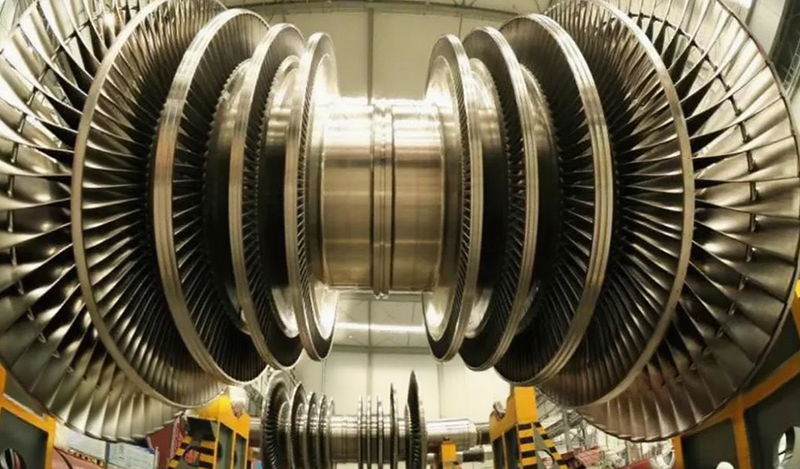

In modern industrial non-destructive testing (NDT) systems, portable industrial videoscopes have become essential inspection tools in critical fields such as aero engines, power generation equipment, petrochemical pipelines, automotive manufacturing, and rail transit. Their core value lies in enabling internal visual inspection without disassembly, allowing efficient and safe assessment of hidden areas such as welds, cavities, and piping systems, thereby significantly improving inspection efficiency and operational safety.

However, with a wide range of models and complex technical specifications available on the market, enterprises often face challenges in selecting the right videoscope that precisely matches their actual working conditions. As a leading domestic manufacturer of industrial videoscopes, Coantec offers this systematic and professional procurement guide based on over a decade of technical expertise and industry experience.

1. Define Inspection Requirements: Start with Application Scenarios

The first step in procurement is not comparing specifications, but systematically analyzing the actual inspection tasks and operational conditions. Consider the following four key dimensions:

1.1 Inspection Object and Structural Characteristics

Is the target an aero engine blade cooling channel, a gas turbine combustor, or a petrochemical pipeline or pressure vessel interior? Key factors such as pipe length, curvature, and minimum internal diameter directly affect equipment accessibility. For example, inspecting a 20-meter-long pipeline with multiple right-angle bends requires a high-mobility model with 360° full-directional steering and ultra-flexible insertion tubes.

1.2 Environmental Conditions

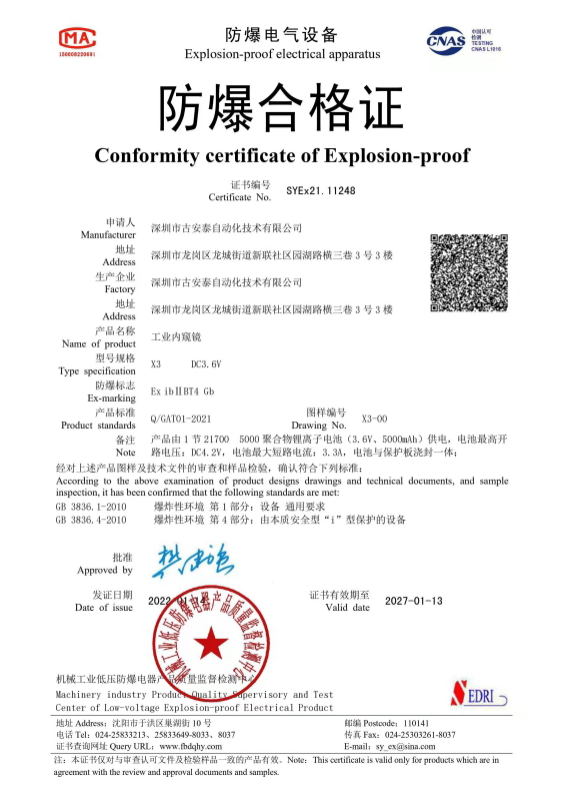

Will the inspection be conducted in high-temperature, oily, corrosive, or explosive environments? For high-risk applications in petrochemical or natural gas facilities, the equipment must be certified for explosion protection (e.g., Ex ib II BT4 Gb) and meet IP67 or higher protection ratings to ensure intrinsic safety.

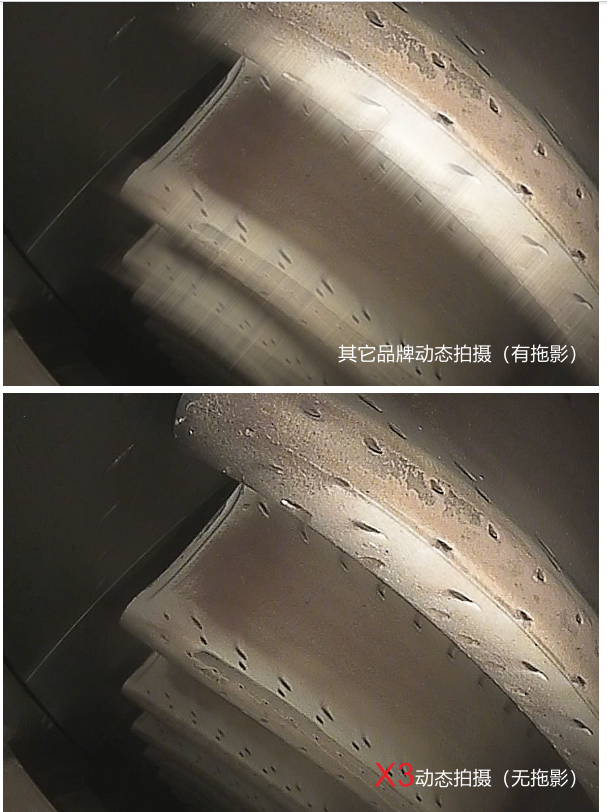

1.3 Imaging and Measurement Accuracy

Is sub-0.1mm crack detection required? Is quantitative defect analysis necessary? For high-precision applications, select models equipped with megapixel CMOS sensors and advanced 3D point cloud modeling capabilities, supporting multi-dimensional measurements (e.g., point-to-point, area, profile), enabling a shift from qualitative observation to quantitative evaluation.

1.4 Operational Efficiency and Data Management

Are inspections frequent? Is standardized reporting required? Prioritize equipment with long battery life, large storage capacity, fast image processing, and automated report generation to enhance inspection efficiency and data traceability.

2. Key Performance Parameters: Technical Specifications That Matter

Once requirements are defined, evaluate the following critical technical parameters:

2.1Probe Diameter and Insertion Tube Length:

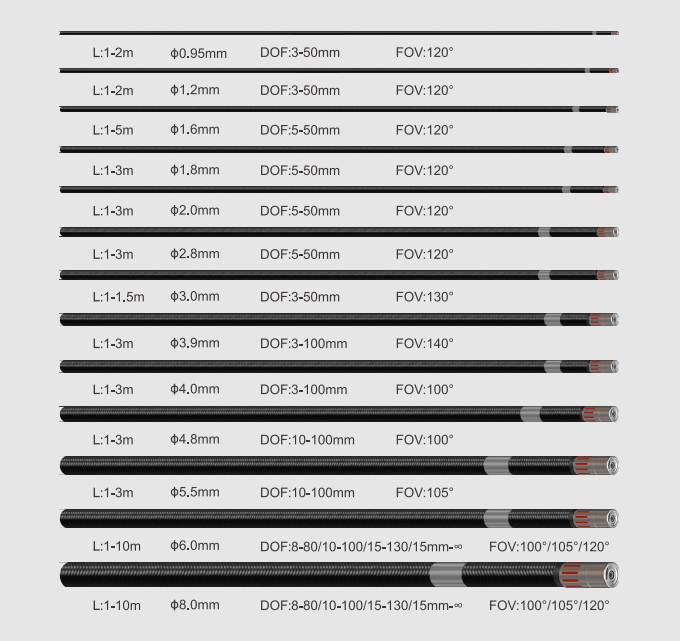

· Select a probe diameter (commonly Φ0.95mm–Φ8.0mm) suitable for the smallest internal diameter of the inspected pipe, with sufficient insertion length (1–10m) to ensure full coverage.

· 2.2Steering Capability:

· 360° joystick-controlled steering and ≥160° single-direction bending angle are essential for navigating complex pathways.

· 2.3Imaging System:

· Opt for OLED or high-brightness LCD screens (≥5.5 inches), with resolution no less than 1280×720, supporting adjustable brightness, contrast, and gamma settings for various lighting conditions.

· 2.4Illumination Options:

· Standard white LED lighting; optional infrared, UV, or laser illumination to enhance imaging in reflective, oily, or low-contrast surfaces.

· 2.5Protection Rating:

· The probe should achieve IP67, and the main unit IP65 or higher, ensuring reliable operation in dusty, oily, and humid industrial environments.

· 2.6Battery and Runtime:

· Dual-battery design (main unit + handle) enables continuous operation of 4.5 hours or more, supporting extended inspection tasks.

3. Brand and Service: Choosing a Trusted Partner

Portable industrial videoscopes are high-value professional instruments. Procurement should not focus solely on price, but also on technical capability and after-sales support.

Choose a manufacturer with:

· In-house R&D capability and ISO 9001 quality management certification;

· Proven industry application cases;

Comprehensive service offerings, including:

· Professional pre-sales consultation and site-specific recommendations;

· Equipment operation training and technical guidance;

· Rapid repair response and spare parts availability;

· Software updates and functional upgrades.

Shenzhen Coantec Automation Technology Co., Ltd. has specialized in industrial videoscopes for over a decade. With independent R&D capabilities and a complete quality management system, Coantec’s products are widely used by thousands of large enterprises globally. We offer end-to-end services from needs analysis and custom solutions to on-site testing and after-sales support, ensuring our customers “buy with confidence and use with peace of mind.”

4. Conclusion: Smart Procurement for Efficient Inspection

Purchasing a portable industrial videoscope is fundamentally a technology-driven decision and long-term value investment. Enterprises should move beyond “specification stacking” and focus on real-world application, comprehensively evaluating safety, adaptability, accuracy, and efficiency to select a truly suitable professional instrument.

The Coantec X3 Series of portable industrial videoscopes integrates explosion-proof safety, high-definition imaging, modular quick-change design, and 3D measurement—engineered for the most demanding, complex, and hazardous environments. It empowers enterprises to achieve blind-spot-free, high-precision, and high-efficiency modern inspection.

For detailed technical documentation or to request a free on-site condition test, please contact the Coantec technical team. We will provide professional, customized solutions tailored to your specific needs.

Hot products

Industrial borescope 3D measurement function - X5 Series

Engine borescope inspection camera Industrial Videoscope- C68 series

Coantec C65 series 3D Measurement High Definition Industrial Videoscope

Super HD Mega Pixel Industrial Videoscope of Coantec C40 series

Tel:+86 13714520051

E-mail:flora@chinavideoscope.com